Featured Service: Construction Surveying

Evolving in the Digital Era Enhances Safety, Accuracy, and Efficiency

If you were to use the phrase “construction surveying” 20 years ago, a near universal image of pounding wooden stakes with brightly colored ribbons into the ground would likely appear in the minds of many in the industry. Today, the phrase is commonly used to describe dramatically evolved and expanded processes, tools and technology that have revolutionized the way construction projects are executed to deliver increased accuracy, efficiency, and safety. In today’s digital era, the data and grade control available through advanced capabilities like 3D modeling and GPS integration empower the team to drive even greater value for our clients.

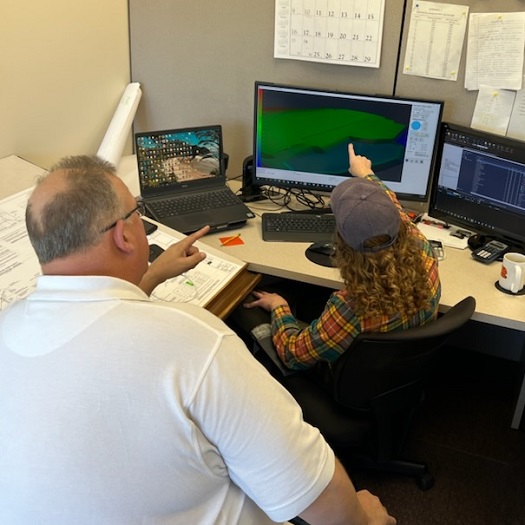

Brubacher’s experienced in-house survey and grade control team works closely with engineers to capture valuable data up front that accurately informs project planning and reduces client risk through all phases of construction. Our Surveying Department converts and interprets the data to create a 3D model that is used by our earthmoving and grading crews. This 3D model, combined with advanced drone technology that identifies topography, dirt and volume calculations, enables Brubacher to provide Insight. On Site. These preparation efforts serve as a reliable bridge between design and constructability, as our team often identifies areas of improvement, and works with the client and their design engineer to address them before work begins.

“In the past, you may not have noticed issues until you were on site and construction had already progressed. Today, we’re creating digital terrain models and can often see where the gaps are, based on how the plan was designed and how it needs to be executed. When buildability issues are identified and resolved in the digital model stage, versus by a crew at a standstill on site, it is a win for everyone. At Brubacher, we strive to be good stewards of our clients’ financial resources and workflow, so we go above and beyond to identify and resolve issues before our boots and equipment hit the ground,” shared Keith Brubacher, President.

The digital transformation in the way site surveying, digital modeling and grade control are managed today has also blurred the lines between surveying, operations, and equipment. The high-quality data captured and interpreted by the surveying team is uploaded to GPS-equipped dozers and excavators. Skilled operators are still vital to safe, efficient machine operation. The GPS capabilities shorten operating learning curves and improve accuracy while also collecting site progress data. Today, there is more data in the cab of the machine than you may have found in a contractor’s entire survey department just 20 years ago. That data is invaluable to project success, but it’s the experience of the team who interprets it during project planning and applies it to real conditions in the field that ensures a project is carried out successfully. At Brubacher, successful construction is a team effort, and the integration of in-house surveying & grade control, operations, and equipment helps the Brubacher team identify and solve more problems before they hold up progress on projects.

In addition to increasing accuracy and efficiency, technology application in site construction is a win for increased safety. In-cab technology has almost eliminated the need for operators to get out and check grade stakes, decreasing the risk of slips, falls, or being struck by other equipment. For the industry veterans reading this…just think about how many times you saw an operator balanced on a track, hood, or blade, straining to see a grade stake through a lock-level!

Leveraging the power of technology, combined with relevant experience, is at the heart of our ability to deliver Insight. On Site. for the clients we are honored to serve. As a team empowered with quality data and an industry-leading fleet of equipment, we can reduce risk, spot and overcome obstacles before they create delays, and drive value through every phase of construction. We always enjoy talking technology and welcome the opportunity to share more about how our in-house capabilities can add value for your next project.